News Single

Focus On Connecting And Cooling

Jade publish the official Tech presentation for Copper 3D Vapor chamber

- 2024-01-08

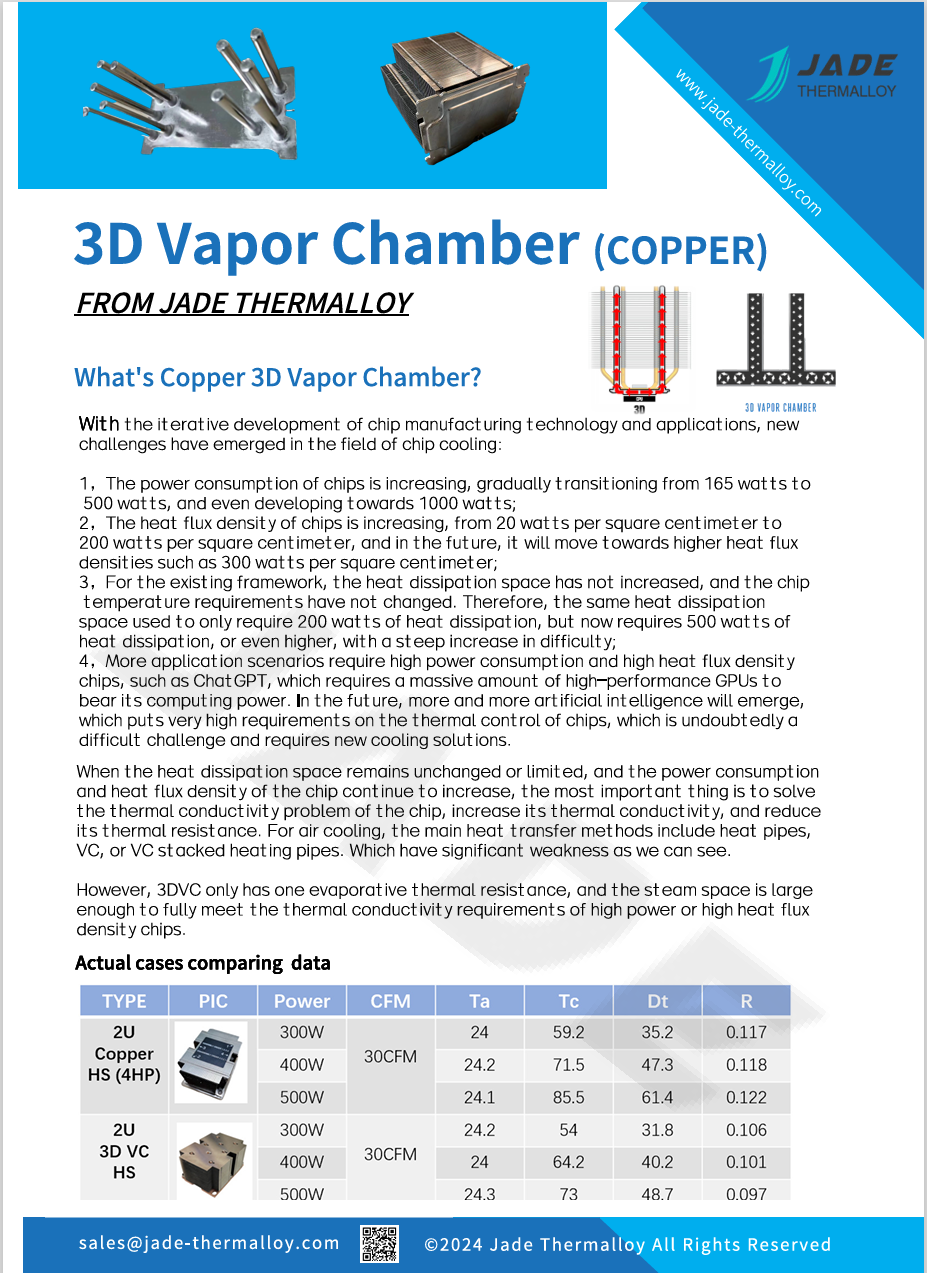

With the iterative development of chip manufacturing technology and applications, new challenges have emerged in the field of chip cooling:

1,The power consumption of chips is increasing, gradually transitioning from 165 watts to 500 watts, and even developing towards 1000 watts;

2,The heat flux density of chips is increasing, from 20 watts per square centimeter to 200 watts per square centimeter, and in the future, it will move towards higher heat flux densities such as 300 watts per square centimeter.3,For the existing framework, the heat dissipation space has not increased, and the chip temperature requirements have not changed. Therefore, the same heat dissipation space used to only require 200 watts of heat dissipation, but now requires 500 watts of heat dissipation, or even higher, with a steep increase in difficulty;

4,More application scenarios require high power consumption and high heat flux density chips, such as ChatGPT, which requires a massive amount of high-performance GPUs to bear its computing power. In the future, more and more artificial intelligence will emerge, which puts very high requirements on the thermal control of chips, which is undoubtedly a difficult challenge and requires new cooling solutions.

When the heat dissipation space remains unchanged or limited, and the power consumption and heat flux density of the chip continue to increase, the most important thing is to solve the thermal conductivity problem of the chip, increase its thermal conductivity, and reduce its thermal resistance. For air cooling, the main heat transfer methods include heat pipes, VC, or VC stacked heating pipes. Which have significant weakness as we can see.

However, 3DVC only has one evaporative thermal resistance, and the steam space is large enough to fully meet the thermal conductivity requirements of high power or high heat flux density chips. Also 3D vapor chamber (3DVC) could fulfill the requirement of energy utilization for electric vehicle (EV) battery thermal management system (BTMS). compared with

the flat shape of conventional vapor chambers (VC).

Summarized by JADE .2024

Search

Categories

Contact Us

- Address: CHN SITE : Huizhou, GuangDong , China

- Phone: +00852-36283398

- Email: sales@jade-thermalloy.com

-

Monday - Friday: 9:00 am - 10:00 pm

Saturday - Sunday: Closed

Say Hey

LiveChatclose